Ball screws are mechanical devices commonly used in a variety of applications where precise linear motion control is required. In missile fin actuation, ball screws are used to control the movement of the fins, which are crucial components that help steer and stabilize the missile in flight.

Helix Linear Technologies Blog | Articles, how-tos and information on the latest linear motion topics.

Ball Screw Linear Actuators: The Future of Precision Motion Control

The ball screw linear actuator is a precision motion control device that has become an essential component in various industries, including automation, aerospace, and robotics. This innovative technology has revolutionized the way motion control systems work, delivering higher accuracy, efficiency, and reliability than ever before.

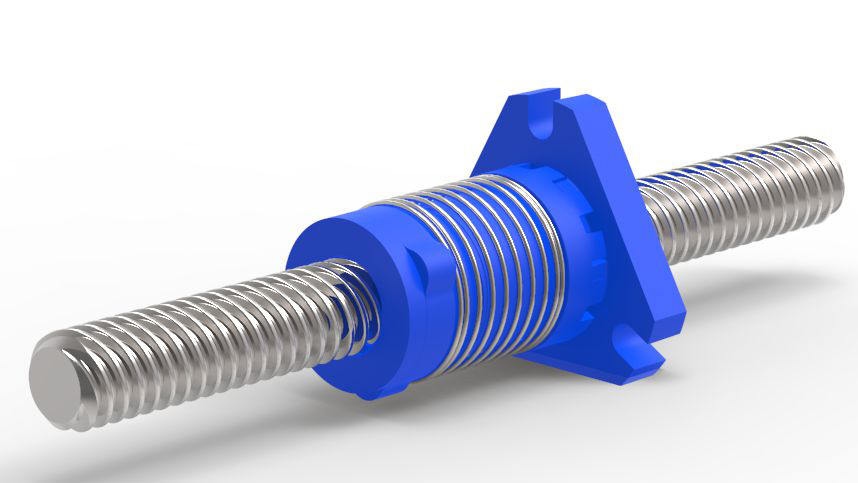

Twin Lead Screw: A Comprehensive Guide to Understanding its Working and Benefits

A twin lead screw, also known as a double lead screw, is a threaded rod used in various machinery applications to convert rotary motion into linear motion. It is essentially two screws placed in parallel with each other, connected by a common shaft. The screw threads on each of the screws mesh with each other, allowing the screws to move in opposite directions. This screw is suitable for use in situations where precision is crucial. and stability is required, such as in CNC machines, printers, and robots. In this article, we will discuss the working of twin lead screws and the benefits they offer.

7 Reasons You Should Consider Ball Screws in Your Linear Motion Application

Ball screws are an essential component in a wide range of machinery and industrial applications, and they offer numerous benefits over other linear motion control options. Here, we'll explore the advantages of ball screws.

5 Reasons Lead Screws Should Be Your Top Choice in Medical Device Design

Lead screws are the ideal solution for many medical devices, providing the precision, durability, and efficiency needed to ensure the best patient care.

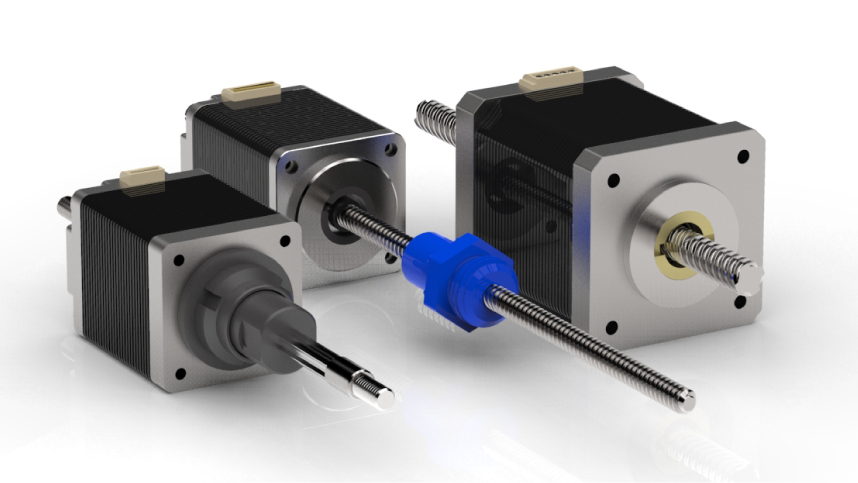

Linear Motion, Physics, and Logic - Common Oversights When Designing Linear Motion Systems

As the saying goes, "The devil is in the details." As simple as your linear motion application may seem, focusing on areas that may cause unexpected problems is highly beneficial. Here are a few important factors to consider when sizing a stepper motor linear actuator that will save work, money, and time in the long run.

Bearing Supports Made EZZE

Bearing end supports for linear actuators is an essential component in your linear actuation application. They ensure load carrying capabilities and long life. They should be sized adequately to handle the axial loads required while supporting the shaft radially.

How to Size a Linear Actuator for Your Application

When selecting the appropriate size of a linear actuator, applying one general number to make a selection, such as a maximum load rating, is difficult.

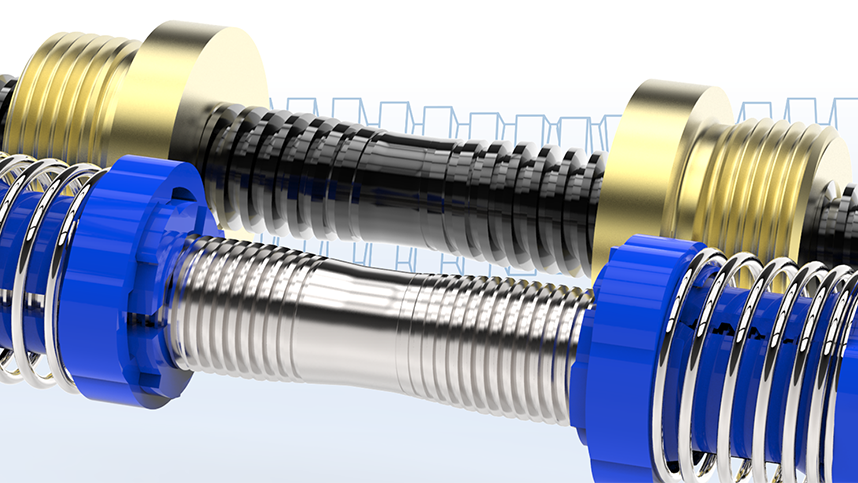

The Ins and Outs of Precision Ball Screw Assemblies

Ball screws are manufactured by rolling or grinding the threads. In some specific situations, they are whirled due to end machining features or tooling availability. Otherwise, rolling and grinding are the primary and preferred methods of ball screw manufacturing.

Precision Linear Motion Suppliers Provide a Lean Advantage in the Medical Equipment Industry

Companies spend millions of dollars each year on improving productivity through Lean initiatives. Kaizen events use Value Stream Mapping and SMED tools to eliminate non-valued added work, reduce cycle times, increase throughput, and improve changeover time. Unfortunately, many of these efforts are not initiated until after a product has been designed and released.