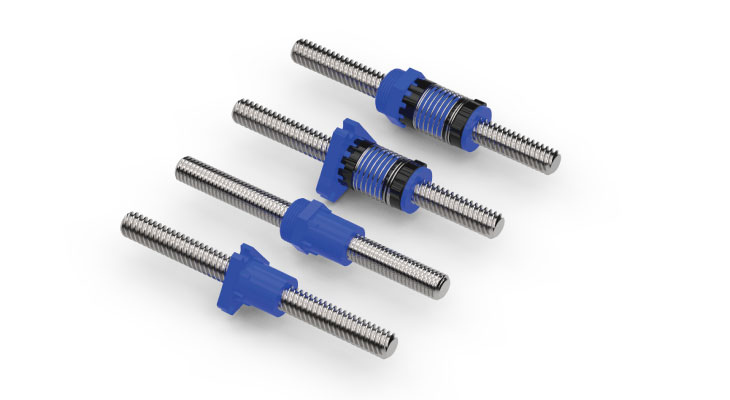

The Most Effective Helix Acme Lead Screw Advantage

Acme screws provide distinct advantages for many of today’s linear motion applications, such as the motion control systems incorporated in many lead screw medical devices. In addition to offering reliable performance and efficiency, precision-engineered Acme lead screws from Helix Linear Technologies provide a more focused, economical solution for integrating motion control systems in many new products.

Lead screws utilize the helix angle of the screw thread to convert rotary motion into linear motion and rely on the coefficient of friction between the nut and screw (dependent on the material from which the nut and lead screw are made) to position loads. Screws are available in various materials, such as carbon steel, stainless steel, aluminum, and titanium, and can be paired with an internally lubricated lead screw plastic or a bearing-grade bronze nut.

Acme screws provide a host of advantages for design engineers who need to solve linear motion challenges that traditionally would have required more expensive ball screws. These advantages include the ability to:

Lead Screw Design with Freedom

Acme lead screws provide design engineers with more design freedom and flexibility because of the variety of available sizes and types. Lead screws, unlike ball screws, which have a rigid form factor and are bulky, the form factor and helix angle of lead screws can be varied widely, enabling you to optimize their configuration to the requirements of your specific application.

Control Costs

Lead screws cost 10-to-75 percent less than ball screws. While the typical cost of a new ball screw design is $50,000-to- to $100,000, a new lead screw generally costs between $3,000 and $8,000. This price disparity represents a significant lead screw advantage, especially when the performance provided by both systems is essentially the same.

Pinpoint Efficiency

Using higher helix angles, you can increase the efficiency of a lead screw to near-ball-screw levels. A higher helix angle produces higher efficiency levels because the number of times the screw must rotate to achieve the same linear displacement is reduced. With high helix screws, when the efficiency level of the lead screw is greater than 50 percent, you can also back-drive an acme screw.

Maximize Speed

Acme screws enable you to take advantage of variable jog speeds and high RPMs. Using a wide range of leads, lead screws can deliver a variation in jog speeds up to 70 inches per second. For devices that need to be positioned with a high level of accuracy, you can utilize a lead screw with a low helix angle to obtain a high positioning resolution. Other advantages of fast jog speeds and low screw RPM are operation and long life.

Eliminate Lead Screw Backlash

Backlash is a concern whenever positioning accuracy is critical. Helix specializes in custom acme lead nuts and anti-backlash nuts that remove the free-play between a nut and a screw without introducing excessive drag torque.

Minimize Noise

Another significant advantage is their quiet operation. Ball screws make noise due to the re-circulation of the ball bearing. Lead screws, on the other hand, generally make little noise when adequately lubricated. Reduced noise levels are an essential requirement in the development of many medical devices.

Reduce Lubrication

Acme lead screws require less lubrication than traditional ball screws. Lead screw assemblies with plastic nuts can run well without lubricant due to the inherent lubricating qualities of the nut material and Teflon coatings on the lead screw. However, using a gel lubricant will increase allowable loading and extend life by reducing friction between the nub and the screw. Helix also offers self-lubricating lead screws.

Resist Corrosion

You can avoid corrosion with Helix lead screws by combining a highly corrosive, resistant stainless steel Acme lead screw with a plastic or bronze acme nut. Anti-corrosion can be increased by Teflon coating the screw as well.

Operate Maintenance-Free

Helix anti-backlash lead screw assemblies are self-adjusting and maintenance-free. The product line also offers simplified installation and adjustment procedures.

Take Advantage of Helix Acme Lead Screws

Before selecting a specific lead screw, check with Helix Linear Technologies to ensure that you’ve configured the best motion control system to use with your particular application. Helix knows acme, and high helix angle lead screws better than anyone and can guide you toward making the right motion control decisions for your products.