Helix Linear Showcases the Most Effective Precision Lead Screws

You already know that lead screws quickly cement themselves as the preferred choice among product developers in linear motion applications. Not only are they more affordable than competing ball screws, thanks to lesser moving parts and greater simplicity. They're also customizable, available in various materials, can be developed with pinpoint accuracy, require less maintenance, and can be made to be anti-corrosive to stand up to the conditions of harsh environments.

But while deciding to incorporate a lead screw into your linear motion application may be an easy decision, what often isn't so easy is deciding on a linear motion partner to supply the screws or assemblies. At Helix, we try hard to make that an easy decision to make. How? We provide our customers with world-class service and support and ensure that every lead screw that we produce is far from your average lead screw.

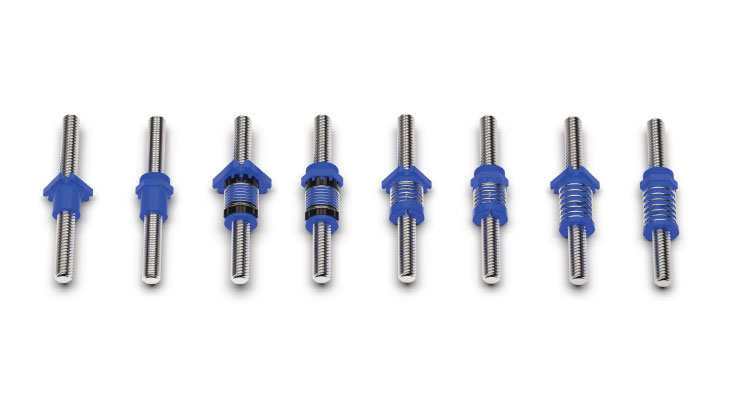

The right lead screw can give your application a competitive advantage -- and Helix can further add to this competitive advantage, as we offer the largest selection of rolled acme and lead screw sizes in the industry. Precision lead screws are created via thread rolling, thread milling, or thread grinding. All processes produce high-precision screws designed to last longer and work better in demanding environments. Screws made via this rolling process are much less costly than ground screws, making Helix screws even more affordable and meaning that these savings can be passed on to the customer. With that being said, screws of greater accuracy can be produced via milled or ground threads. Helix lead screws are all created in a state-of-the-art 40,000-square-foot facility.

So just what else helps differentiate a Helix lead screw from the rest of the pack? Here's a look:

- Material Availability: We already mentioned how lead screws are available in a variety of materials. Helix specializes in creating screws from materials ranging from carbon steel to aluminum to titanium. For screws that need to operate in extreme manufacturing environments, stainless steel materials are available as well. Specifically, Helix specializes in fabricating screws with 300 Series stainless and 4140 Series materials. Still, Helix can pair your lead screw with the appropriate material for maximum efficiency no matter what your application is. Helix also offers self-lubricating lead screw assemblies for hard-to-maintain applications.

- Custom Thread Forms: When we say that we can create lead screws that are application-specific, we mean it. This is evidenced by our ability to fabricate custom thread forms for customers. Furthermore, Helix offers screws in any diameter, lead combination, and custom end machining.

- Nut Design: Another significant factor differentiating Helix from the rest of the competition is its ability to custom design and engineer lead nuts. As you know, the nut design is just as important as the lead screw design. Helix can create custom nuts via injection molding or machining for maximum performance, no matter what the application demands or the environmental conditions dictate.

- Flexibility: Again, it's worth mentioning how flexible Helix screws are, as they permit designers and engineers to focus on the optimal design rather than having to compromise the application to incorporate a less flexible technology option. And our advanced manufacturing know-how and processes further cement this advantage. You might say that our products are a designer's best friend, especially when considering how easy it is to configure and download 2D and 3D models of our products and insert them right into your design.

- Vertical Applications: Helix screws are also designed to be self-locking under certain conditions, making them an ideal choice for vertical applications.

As you can see, Helix lead screws aren't your average lead screw. They're highly advanced, flexible, and can be custom-made for any application. It's the Helix advantage.