Why You Should Consider a Stainless Acme Lead Screw for Your Project!

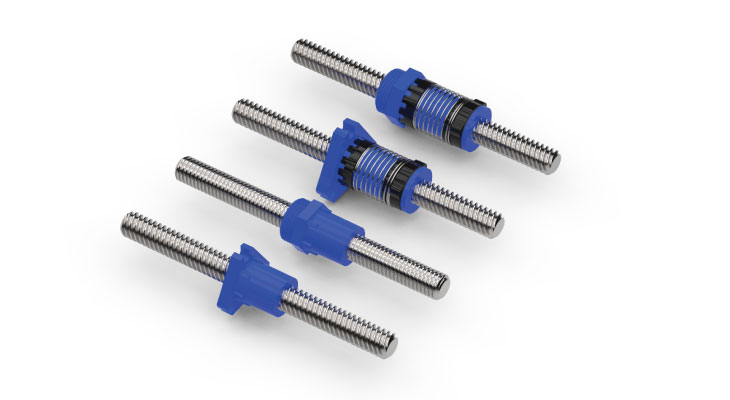

Acme lead screw assemblies are the preferred choice of many for linear motion applications, partially because they're very flexible, coming in "many flavors," so to speak. One example of this is how many material combinations are available between the screw and the nut. To name a few, nuts are available in Delrin (acetal), PEEK (polyether ether ketone), PET-P (polyethylene terephthalate), PAI (polyamide-imide), bronze, steel, and stainless steel. Helix also makes screws in a variety of alloy and stainless steel as well. Combined with our array of nut materials that means we can deliver a combination just right for your application. To further fine-tune performance, screws can also have different coatings such as black oxide or PTFE.

At Helix, we specialize in fabricating lead screws with 300 Series stainless steel. This family of stainless steel resists corrosion and maintains strength over a wide temperature range. If your application is utilized in more extreme environments, a stainless steel lead screw could be just the right solution for you.

Here's a closer look at some of the benefits of electing to use stainless steel material for your acme lead screw:

- Corrosion Resistance: Stainless steels offer resistance to corrosion to varying degrees by way of their chromium content. Stainless steels develop a tightly bonded layer of chromium oxide that protects the surface and underlying material from oxygen diffusion. The chromium oxide layer can even "heal" itself if scratched so long as sufficient oxygen is present. Harsh environments like automotive, aerospace, and construction applications are ideal for this variety of screws.

- Temperature Resistant: Not only are stainless screws tough and durable, but they will also maintain these properties at very high and shallow temperatures.

- Easy to Manufacture: One significant benefit of acme lead screws, in general, is their comparatively low cost when compared to other technologies. One of the reasons Helix screws are less expensive to manufacture is that they are produced by a rolling process which is much faster than machining or grinding. Stainless steel can be rolled, which allows us to take advantage of the cost-benefit of the rolling process. Stainless steel is also able to be cut, welded, and machined with relative ease.

- Cost: Not only are stainless steels easy to manufacture and fabricate, but when you consider total life cycle costs, it's this type of material that often scores best. That's right, compared to other materials; it's stainless that usually wins the life cycle cost comparison.

- Hygienic: Stainless steels are also more easily cleaned - meaning that they are generally easier to maintain than other types of materials.

Now that you know some of the general benefits of selecting stainless over other materials, let's take a closer look at some of the more popular 300 Series stainless steels that we use at Helix and their properties:

- 302 Stainless: A standard chrome-nickel stainless that is also heat resistant. It offers a tensile strength of 100,000 psi and a hardness Rockwell of B85, making this material ideal for applications ranging from food and beverage to sanitary.

- 304 Stainless: 304 stainless steel is the most popular and most widely used of all stainless steel. It's non-magnetic and versatile, offering a lesser carbon composition to minimize carbide precipitation. It's most commonly used in extremely high-temperature applications. It's also resistant to corrosive acids. Additionally, 304 Stainless has a tensile strength of 95,000 psi and a hardness Rockwell of B80.

- 316 Stainless: An ideal material for use in the chemical, food, and oil and gas industries, 316 Stainless has a low carbon content to avoid carbide precipitation. It adds molybdenum and offers a slightly higher nickel content than other types of 300 Series stainless steels and features a tensile strength of 90,000 psi and hardness Rockwell of B80.

To review, when it comes to acme lead screw assemblies, the material options are plentiful, from PEEK to bronze and beyond. But the application that you're working on should always dictate the type of material you select. For more extreme environments, a stainless steel acme lead screw may be the right option for your linear motion application and something that you should consider.